Ball Screw Repair > Ball Screw Installation Tips

Ball Screw Installation Help.

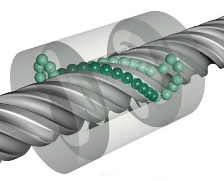

When a precision ball screw assembly is rebuilt by an experienced and reputable ball screw repair specialist, you should expect it to run smoothly and position accurately with good repeatability. A long service life is also expected but it is important to realize there are many other factors involved after it leaves the supplier or repair shop.

Installing. While having your ball screw repaired, it is a good idea to replace the thrust bearings (angular contact bearings) and radial bearings (support bearings). You can usually order these through your local bearing supply but sometimes you have to go through the machine manufacturer to purchase them. When installing your reconditioned ball screw assembly , always be sure to check for the following:

· Cleanliness. It is very important that you keep the ball screw, mounting surfaces, and bearing journals clean and in good condition. If debris or damage is present on the surfaces between the ball nut flange and the mounting surface on the table or slide, the ball nut can become misaligned on the screw and the ball screw is sure to fail. This is a common mistake during ball screw installation. Always check for small nicks and debris on mounting surfaces.

· Alignment. A ball screw should always be aligned correctly in a CNC machine if you expect it to perform well, and with longevity. If the ball screw is not installed parallel with the table or slide, the ball nut will tighten as it travels towards the ends of the screw, which puts the ball nut under extreme radial load and will cause the ball screw to fail. Some ball screws have adjustable bearing blocks while others use spacers or shims for adjustment. Always have your ball screw assembly installed by a knowledgeable and experienced machine tool technician.

· Lubrication. Some of the most common reasons ball screws fail is lack of lubrication, wrong lubricant, or contaminated lubricant. Be sure the machines lubrication system is clean and working properly. Stay away from synthetic and moly (molybdenum disulfide) greases. To determine which lubricant you should be using, always check with the (OEM) machine manufacturer.

Transportation. While in transit, it is important that a reconditioned ball screw assembly is protected from the following:

· Moisture. Moisture leads to corrosion which can cause immediate damage to the fine surface finishes of a ball screw, especially in the thread radius.

· Contamination. Foreign objects that stick to the surface of the ball screw can potentially get past the ball nut wiper and end up inside of the ball nut. Even a small particle of grit can do permanent damage to the thread radius, the balls, and the ball return system.

· Damage During Shipping. A new or reconditioned ball screw will be protected from the elements during shipping when a protective coating is applied to prevent corrosion and the unit is covered in a plastic sleeve to protect it from contaminants and moisture. The ball screw should also be packed in a suitable container such as a wooden box or a PVC tube with adequate interior support. Packing a ball screw assembly properly will protect it when it is dropped or bumped. A small nick on the surface of a ball screw can cause it to fail very quickly after installation.